Surgeon/Restorative dentist:

Dr. Leonardo Targetti – Florence, Italy

This case demonstrates the clinical and laboratory procedures for an implant-supported prosthesis with a new type of overdenture attachment system which uses conometric friction retention instead of ball attachment or Locator attachment. The conometric attachment system consists in titanium abutments (MUA-Conics), with a 5-degree (half angle) tapered top and preformed conometric caps, made of PEEK, with an internal connection with the same taper angle, which are incorporated within the overdenture.

This innovative conometric attachment system offers excellent retention giving the patient the comfort of a fixed prosthesis, while remaining easy to insert and to remove for daily hygiene. The conometric caps are fabricated in PEEK and thus almost wear-free. Conometric-retained overdentures can also be fabricated in case of non-parallel implants thanks to straight and angled (7,5° – 15° – 25° – 35°) abutments in 4 different gingival heights with no limits on positioning (XCN® 360° connection).

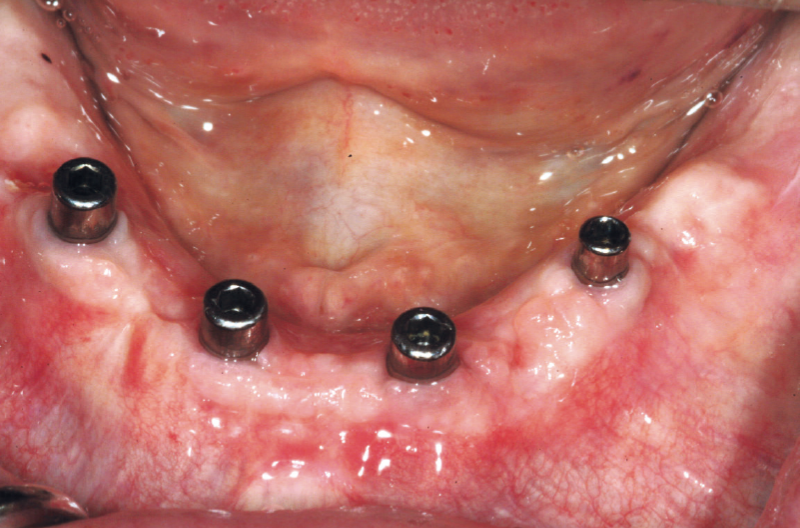

Clinical situation at time of implant level impression taking: view of healing caps on three 4.1×12 mm Classix Leone implants and one 3.3×12 mm Classix Leone implant

Occlusal view of the provisional overdenture

Ridge-side view of the provisional overdenture: the denture base was relieved over the healing caps and relined

Ridge-side view of the provisional overdenture: the denture base was relieved over the healing caps and relined

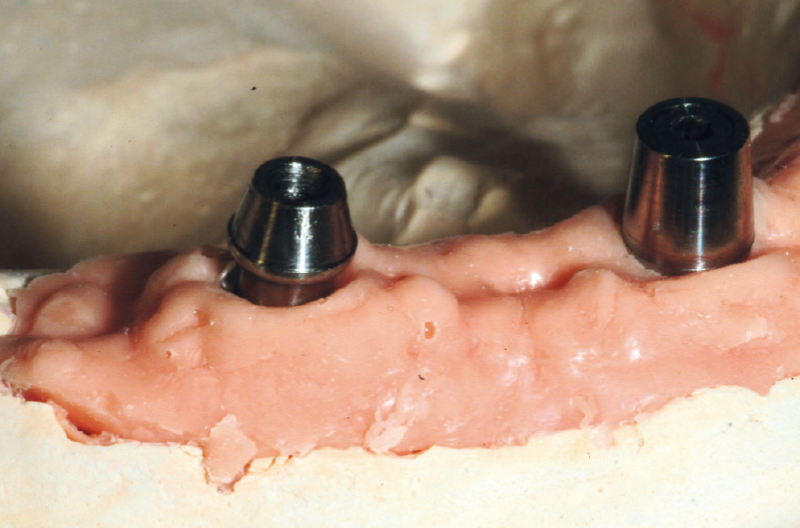

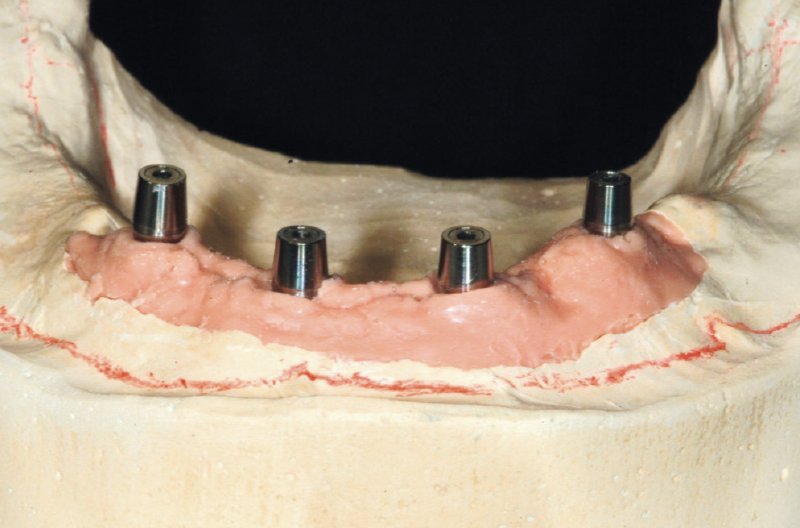

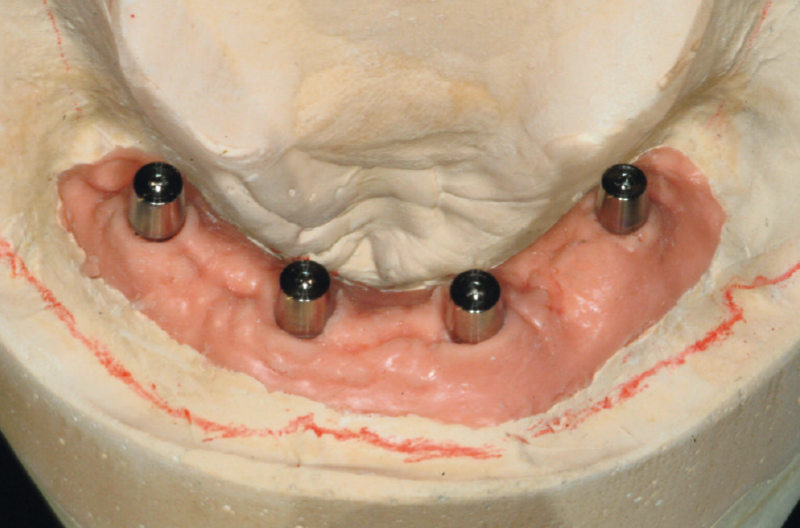

Dental cast after implant-level impression: four straight MUAs GH 1.5 mm were selected and properly tapped into the analogs

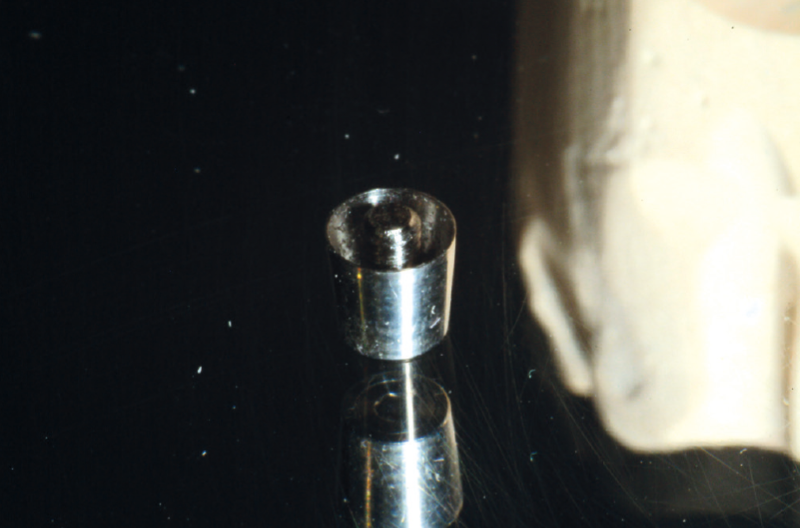

Conic Adapter used to convert MUA into conometric abutment (MUA-Conic)

Conic Adapters screwed onto MUAs to convert into MUA-Conics and tightened by means of the lab torque screwdriver

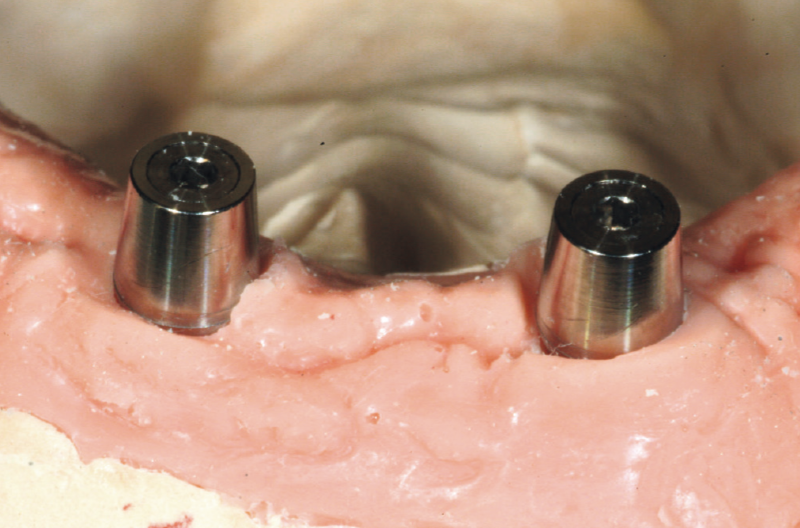

Detail of two MUA-Conics

View of MUA-Conics parallel to each other

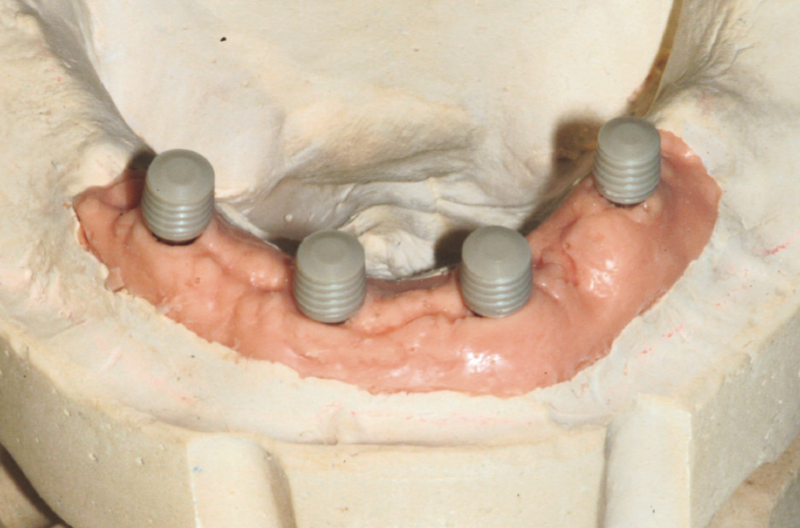

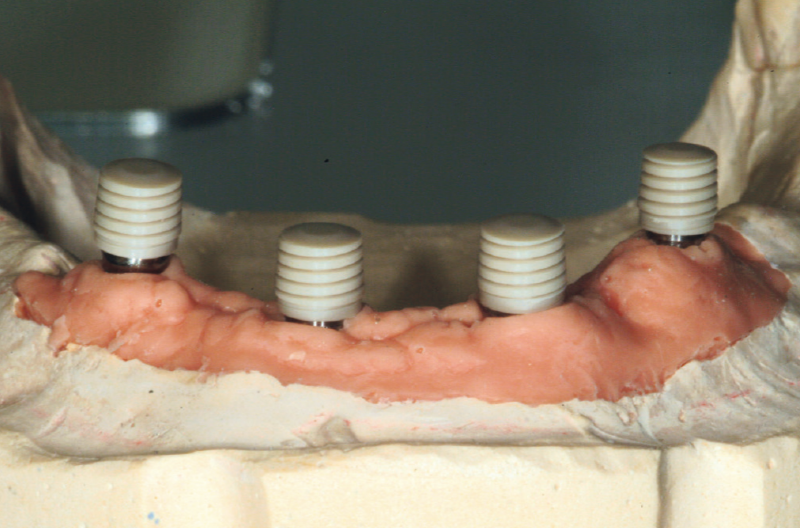

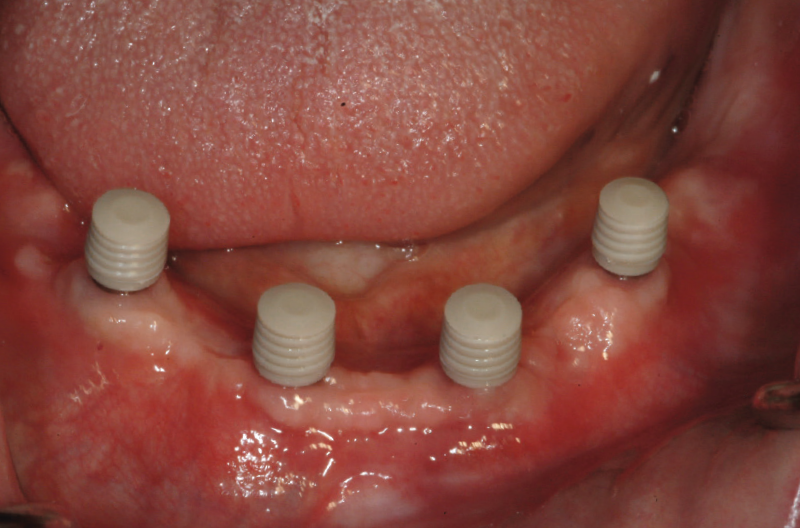

Mobile caps, made of PEEK, placed with decisive manual pressure onto MUA-Conics. Note that prototypes of Mobile caps were beige; today they are pink

Mobile caps, made of PEEK, placed with decisive manual pressure onto MUA-Conics. Note that prototypes of Mobile caps were beige; today they are pink

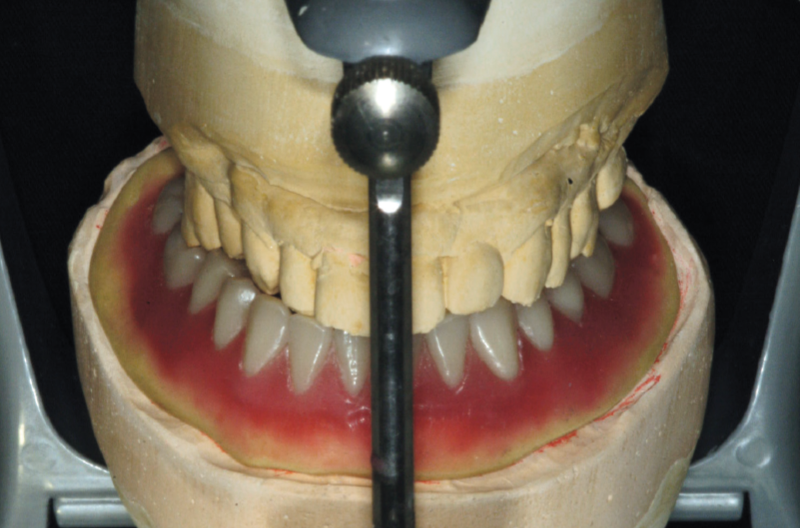

Fabrication of the definitive overdenture: view of the prosthesis on the articulator

Definitive overdenture on dental cast: ready for functional and esthetic intraoral try-in

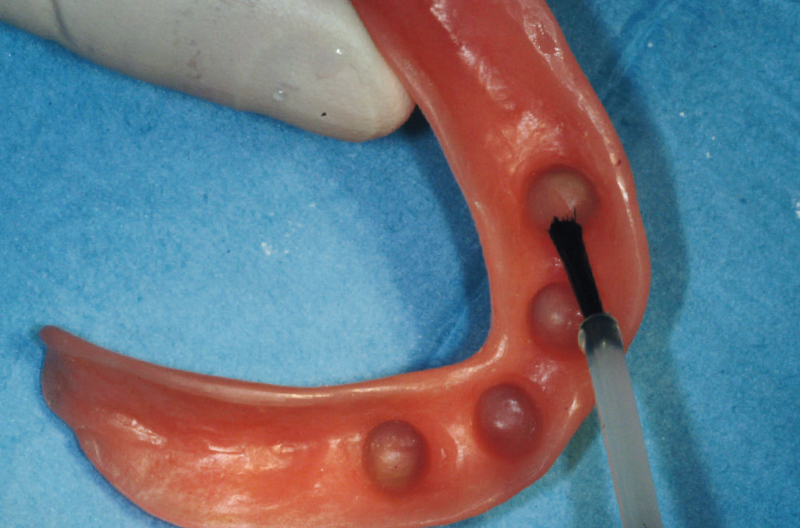

Ridge-side view of the definitive overdenture during fabrication: bores with sufficient space for conometric caps and acrylic

Ridge-side view of the finished definitive overdenture

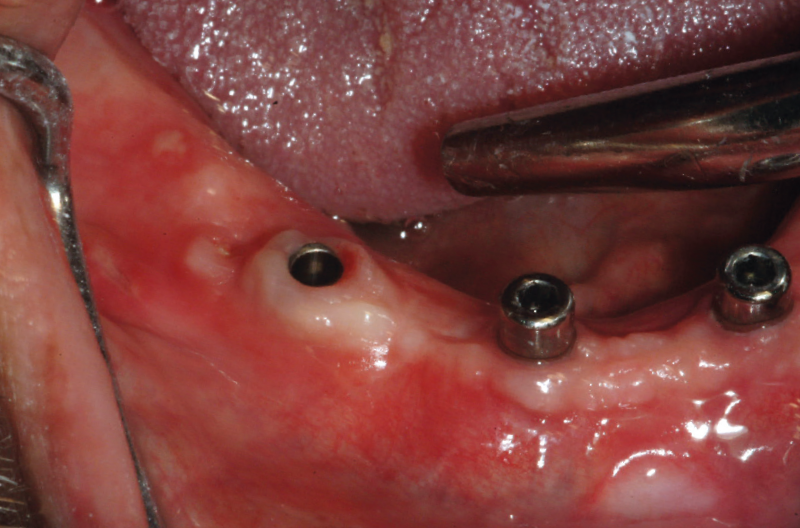

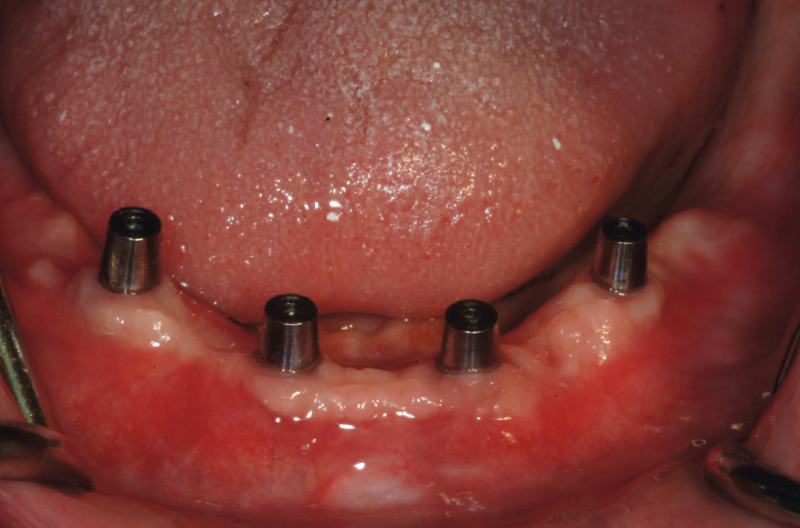

Clinical situation at time of delivery of definitive overdenture: view of healing caps

Removal of healing caps

MUA-Conics properly tapped into the implants

Mobile Caps properly tapped onto MUA-Conics

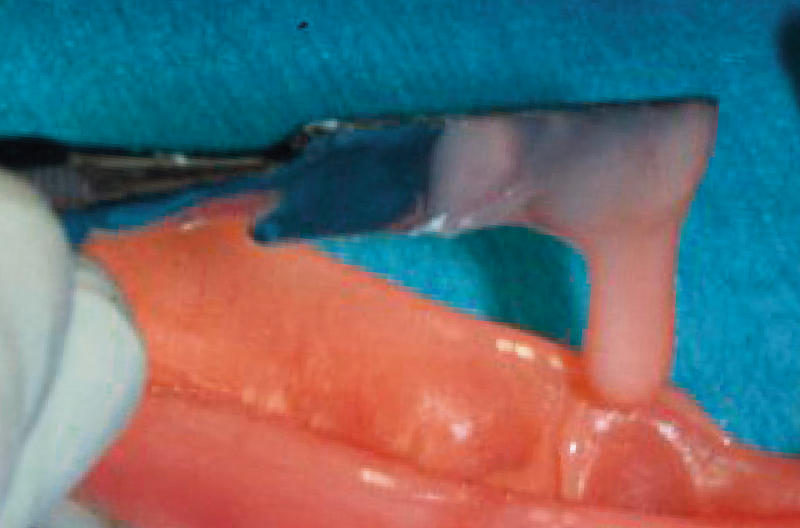

Abutment seater with straight and offset PEEK tip used to tap the abutments into the implant and to seat the Mobile Caps with a gentle tapping force on the abutments

Adhesive application

Adhesive application

Application of acrylic into the bores

Definitive overdenture placed into position in the mouth

Ridge-side view of the finished overdenture: Mobile Caps are incorporated within the overdenture and excess acryl has been removed

Definitive overdenture in place

Clinical situation two and a half years after delivery of the overdenture: view of healthy and stable soft tissues

Ridge-side view of the overdenture two and a half years after delivery: Mobile caps show no signs of wear

Ridge-side view of the overdenture two and a half years after delivery: Mobile caps show no signs of wear

Overdenture again in place – during two and a half years no repairs were necessary

Laboratory:

Alessandro Nannucci – Florence, Italy